High reputation Co2 Laser Engraving Machine - Jewelry Laser Welding Machine – Inbuilt Water Chiller – Bec Laser

High reputation Co2 Laser Engraving Machine - Jewelry Laser Welding Machine – Inbuilt Water Chiller – Bec Laser Detail:

Product Introduction

Manufacturing and retail jewelers currently using laser welders are often amazed at the wide range of applications and the ability to produce a higher quality product in less time with fewer materials while eliminating excessive heat effects.

One of the key elements in making laser welding applicable to jewelry manufacturing and repair was the development of the “free-moving” concept. In this approach, the laser generates a stationary infrared light pulse which is targeted through the microscope’s cross-hair. The laser pulse can be controlled in size and intensity. Because the heat generated remains localized, operators can handle or fixture items with their fingers, laser welding small areas with pin-point accuracy without causing any harm to the operator’s fingers or hands. This free-moving concept enables users to eliminate costly fixturing devices and increase the range of jewelry assembly and repair applications.

Jewelry laser welding can be used to fill porosity, re-tip platinum or gold prong settings, repair bezel settings, repair/resize rings and bracelets without removing stones and correct manufacturing defects. Laser welding reconfigures the molecular structure of either similar or dissimilar metals at the point of welding, allowing the two common alloys to become one.

Features

1. High quality: 24 hours of continuous working ability, the cavity life is 8 to 10 years, xenon lamp life of more than 8 million times.

2. The user-friendly design, in line with ergonomic, working long hours without fatigue.

3. Stable performance of the whole machine, electric adjustable beam expander.

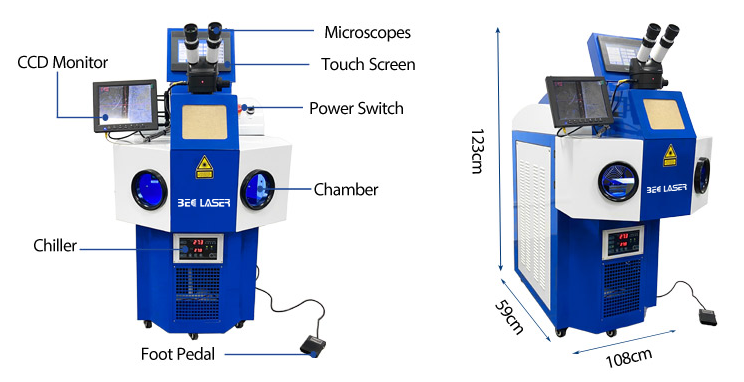

4. 10X microscope system based on pioneered the use of high definition CCD observation system to ensure spot effect in appearance.

Application

Widely applicable to all kinds of micro parts of precision welding, such as jewelry, electronics, dental, watches, military. It is suitable for most metal materials like platinum, gold, silver, titanium, stainless steel, cooper, aluminum,other metal and alloy.

Parameters

| Model | BEC-JW200I |

| Laser Power | 200W |

| Laser Wavelength | 1064 nm |

| Type of Laser | ND:YAG |

| Max. Single Pulse Energy | 90J |

| Frequency Range | 1~20Hz |

| Pulse Width | 0.1~20ms |

| Control System | PC-CNC |

| Observation System | Microscope & CCD monitor |

| Parameter Adjustment | External Touchscreen and Internal Joystick |

| Cooling System | Water cooling with inbuilt water chiller |

| Working Temperature | 0 °C – 35 °C ( No condensation) |

| Total Power | 7KW |

| Power Requirement | 220V±10% /50Hz and 60Hz compatible |

| Packing Size & Weight | Around 114*63*138cm, gross weight around 200KG |

Samples

Structures

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our merchandise and service. At the same time, we do the job actively to do research and improvement for High reputation Co2 Laser Engraving Machine - Jewelry Laser Welding Machine – Inbuilt Water Chiller – Bec Laser , The product will supply to all over the world, such as: Casablanca, Poland, Croatia, With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.