Hot New Products Fiber Laser Engraving Machine 50w - 3-Axis Laser Welding Machine-Automatic Type – Bec Laser

Hot New Products Fiber Laser Engraving Machine 50w - 3-Axis Laser Welding Machine-Automatic Type – Bec Laser Detail:

Product Introduction

Laser welding uses high-energy laser pulses to locally heat a material in a small area. The energy of laser radiation diffuses into the material through heat conduction, and the material is melted to form a specific molten pool. It is a new type of welding method, mainly for the welding of thin-walled materials and precision parts. It can realize spot welding, butt welding, stitch welding, sealing welding, etc., with high aspect ratio, small weld width, and small heat affected zone. Small deformation, fast welding speed, smooth and beautiful welding seam, no need or simple processing after welding, high welding seam quality, no air holes, precise control, small focus spot, high positioning accuracy, and easy to realize automation.

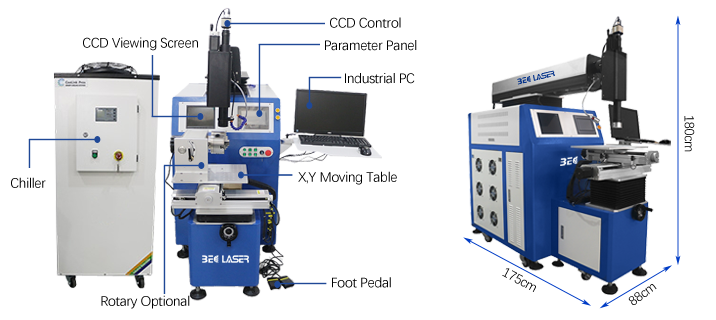

The whole applied three axes design( four axes available), the X,Y worktable can be adjusted automatically. The height of the work bench and laser path also adjustable. Software carry out the welding trace movement, welding spot, straight line, circle, oval and square etc. any plane trace and simple space geometry trace. Besides, this machine can be used to repair large-scale moulds weighing tons, with the help of vibration-proof trundle and self-balanced foot stand, it is easy to remove of fasten this product.

Features

1. The laser source uses German advanced technology, modular gilded cavity. It has the character of high output energy, stable performance and easy maintenance.

2. It has an automatic control system software which can achieve high precision contour control and speed control, while a wealth of logic control capabilities. Improved the work efficiency greatly.

3. The laser power is stimulated by di-pulse XE-lamp, controlled by constant-current pulse, programmed by intelligence program.

4. Touch screen panel to adjust the parameters, which is simple and convenient.

5. The work bench can be lifted, and moved in three dimensions automatically. The laser head and workbench also can be lifted up & down manually.

6. CCD monitor let the operator to observe the working trace more clearly.

7. Rotary device optional for cylindrical annular objects repair.

Application

It is applicable to welding kettles, vacuum cups, stainless steel bowls, sensors, tungsten, filaments, high power diodes (triodes), aluminum alloys, laptop enclosures, mobile handset batteries, door handles, dies, electrical appliance parts, filters, oil nozzles, stainless steel products, golf club heads, zinc alloy craftworks, and so on.

Parameters

| Model | BEC-AW200 | BEC-AW300 | BEC-AW400 | BEC-AW500 |

| Laser Power | 200W | 300W | 400W | 500W |

| Laser Wavelength | 1064 nm | |||

| Max. Single Pulse Energy | 80J | 100J | 120J | 150J |

| Laser Type | ND:YAG | |||

| Laser Pulse Frequency | 0.1-100Hz | |||

| Pulse Width | 0.1-20ms | |||

| Workbench | X=350mm, Y=200mm, bearing up to 200KG | |||

| X, Y, Z Movement | X, Y Axis move automatically; range 300×300mm (Optional), Z-axis can be lifted. | |||

| Observing Systems | Microscope and monitoring system CCD image to enlarge | |||

| Control System | PLC or PC & Microcomputer program control | |||

| Power Consumption | 6KW | 10KW | 12KW | 16KW |

| Cooling System | Water cooling | |||

| Power Requirement | 220V±10%/380V±10% 50Hz or 60Hz | |||

| Packing Size & Weight | Machine: 90*175*182cm, Water chiller:87*80*182cm; Gross weight around 660KG | |||

Samples

Structures

Details

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for Hot New Products Fiber Laser Engraving Machine 50w - 3-Axis Laser Welding Machine-Automatic Type – Bec Laser , The product will supply to all over the world, such as: Auckland, Costa rica, Salt Lake City, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!