Manufactur standard Jewelry Etching Machine - Cantilever Laser Welding Machine-With Lazy Arm – Bec Laser

Manufactur standard Jewelry Etching Machine - Cantilever Laser Welding Machine-With Lazy Arm – Bec Laser Detail:

Product Introduction

The mold laser welding machine is also a branch of the laser welding machine. The working principle is to use high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation is diffused into the material through heat conduction, and the material is melted to form a specific Molten pool.

It is a new type of welding method, mainly for the welding of thin-walled materials and precision parts. It can realize spot welding, butt welding, stitch welding, sealing welding, etc., with high aspect ratio, small weld width, and small heat affected zone. Small deformation, fast welding speed, smooth and beautiful welding seam, no need or simple processing after welding, high welding seam quality, no air holes, precise control, small focus spot, high positioning accuracy, and easy to realize automation. High-power laser welding machines have been introduced, which can realize various types of laser welding machines and repairs for thicker materials.

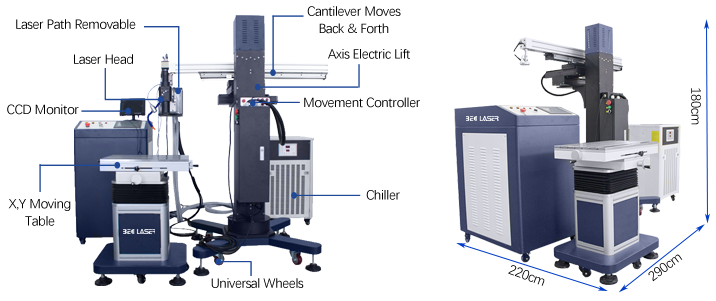

The cantilever arm can be turned to all directions and angles. Even the mould can not be move, the cantilever arm can move freely, greatly solve the welding difficult, enhance the working efficiency. The machine can weld narrow place, deep cavity repair welding, will not hurt the surrounding wall. It will not deform the mold product or sink around the weld pool.

Features

1. The laser source uses German advanced technology, modular gilded cavity. It has the character of high output energy, stable performance and easy maintenance.

2. Touch screen panel to adjust the parameters, which is simple and convenient.

3. The work bench X,Y movement using precision ball screw and high-precision straight guide rail light and flexible, accurate positioning, bearing up to 200 kg;

4. The laser head can slide back and forth, manual lifting, laser head can be easily rotated 180 degrees, easy to repair welding any side;

5. Equipped with remote control, flexible adjustment of 360 degrees angle position of welding. In view of the large mould, don’t need the workbench, directly on the ground or forklift mold welding.

Application

It used for big molds repairing/re-shaping. Materials that can be welded are extensive: cold work alloy steel, hot work alloy steel, nickel tool steel, steel alloy, high tenacity aluminum alloy, etc. Other metals like brass, aluminum-magnesium alloy, titanium, and platinum are also applicable.

Parameters

| Model | BEC-MW200C | BEC-MW300C | BEC-MW400C | BEC-MW500C |

| Laser Power | 200W | 300W | 400W | 500W |

| Laser Wavelength | 1064 nm | |||

| Max. Single Pulse Energy | 80J | 100J | 120J | 150J |

| Laser Type | ND:YAG | |||

| Laser Pulse Frequency | 0.1-100Hz | |||

| Pulse Width | 0.1-20ms | |||

| Workbench | Platform moving range: X=250mm, Y=150mm, bearing up to 200KG | |||

| Cantilever Movement | X=370mm, Y=370mm, Z=850mm | |||

| Observing Systems | Microscope or CCD monitor optional | |||

| Control System | Microcomputer program control | |||

| Power Consumption | 6KW | 10KW | 12KW | 16KW |

| Cooling System | Water cooling | |||

| Power Requirement | 220V±10%/380V±10% 50Hz or 60Hz | |||

| Packing Size & Weight | Machine: 295x105x195cm, Water chiller:60x58x108cm; Gross weight around 510KG | |||

Samples

Structures

Details

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for Manufactur standard Jewelry Etching Machine - Cantilever Laser Welding Machine-With Lazy Arm – Bec Laser , The product will supply to all over the world, such as: Slovakia, Turkey, Costa Rica, Our company always concentrate on the development of the international market. We've got a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.