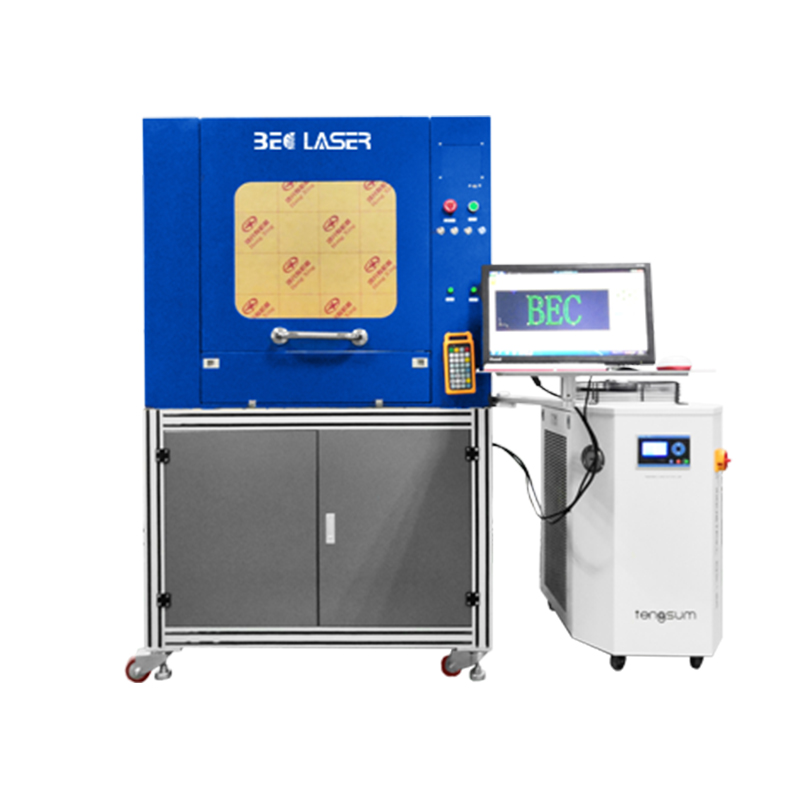

Manufacturer for Laser Cutter And Engraver – Jewelry Laser Cutting Machine – Bec Laser

Manufacturer for Laser Cutter And Engraver – Jewelry Laser Cutting Machine – Bec Laser Detail:

Laser cutting is the preferred method of making name cut outs and monogram necklaces. One of the most widely-used jewelry applications for lasers, cutting works by directing a high-powered laser beam at the sheet of metal chosen for the name. It traces the outline of the name in a font selected within the design software, and the material exposed is melted or burned away. The laser marking systems are accurate to within 10 micrometers, which means the name is left with a high-quality edge and a smooth surface finish, ready for the jeweler to add loops for attaching a chain.

Jewelry designers and manufacturers are continually looking for reliable solutions for producing precision cutting of precious metals. Fiber laser cutting with high power levels, improved maintenance and better functionality is emerging as a top choice for jewelry cutting applications, particularly applications where superior edge quality, tight dimensional tolerances and high production is required.

Laser cutting systems can cut a wide variety of materials of varying thickness and are well suited for creating complex shapes. In addition, fiber lasers maximize precision, cut flexibility and throughput and offer a cost effective high accuracy cutting solution while at the same time providing jewelry designers freedom to create challenging shapes unconstrained by traditional cutting methods.

With a laser cutting system you can easily create complex cutting patterns for your jewelry designs.

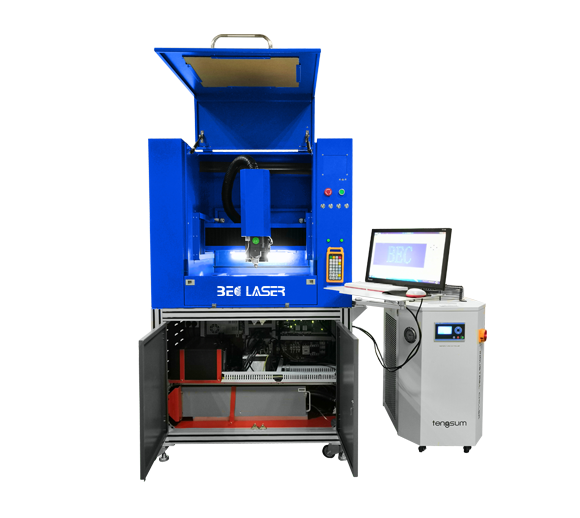

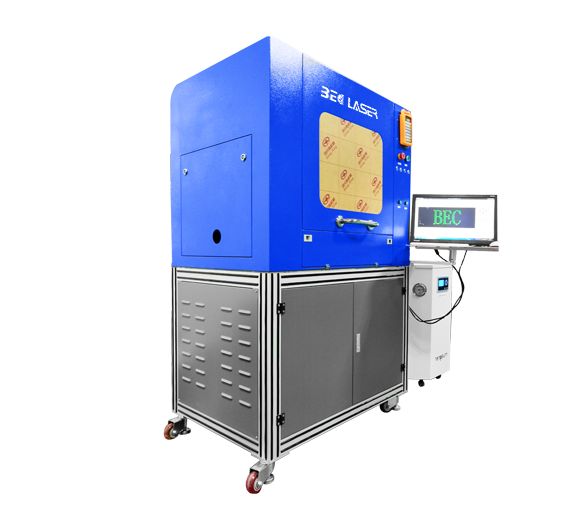

Product Introduction

BEC jewelry laser fiber laser cutting with high power levels, improved maintenance and better functionality is emerging as a top choice for jewelry cutting applications, particularly applications where superior edge quality, tight dimensional tolerances and high production is required. It can cut a wide variety of materials of varying thickness and are well suited for creating complex shapes.

Features

1. Minimal distortion on parts due to a small heat affected zone

2. Intricate part cutting

3. Narrow kerf widths

4. Very high repeatability

Type of Metals Used for Laser Cutting

Name cut out pendants come in a variety of metals. Whether the customer chooses gold, silver, brass, copper, stainless steel or tungsten, laser cutting remains the most accurate method of creating the name. The range of options means this is a trend that isn’t exclusive to women; men typically prefer heavier metals and a bolder font, and jewelers generally try to accommodate all preferences. Stainless steel, for example, is popular with men because it has a slightly more casual feel about it, and laser cutting works better on the metal than any other fabrication method does.

Application

All commonly used precious metal alloys and also many other metal materials such as brass, aluminum, stainless steel, titanium, silver, copper, gold, brass and so on can be cutted with high accuracy. Material thicknesses which can be processed range from thin foils up to 5 mm.

Parameters

| Model | C500R | C750R |

| Laser Power | 500W | 750W |

| Laser Wavelength | 1064±5 nm | |

| Pulse Repetition Frequency | 10-50kHz | |

| Cutting Speed | 600-1500mm/min | |

| Max. Single Pulse Energy | 25 @ 20kHz | 50 @ 20kHz |

| Working Area | X=350mm, Y=240mm | |

| Proximity Switch | Omron, Japan | |

| Electrical Components | Schneider, French | |

| Software | Cypercut | |

| Cooling System | Water cooling | |

| Cutting Air Pressure | 8-12bar (Oil-free, anhydrous, dry gas) | |

| Optional Parts | Dust recovery and purification system | |

| Power Requirement | 220V±10% /50Hz or 60Hz | |

| Packing Size & Weight | Machine: 1800*1100*870mm, Water chiller: 60*80*80mm; Around 490KG | |

Samples

Structures

Details

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of Manufacturer for Laser Cutter And Engraver – Jewelry Laser Cutting Machine – Bec Laser , The product will supply to all over the world, such as: Madras, French, Provence, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.