New Delivery for Aluminum Laser Marker - Mold Laser Welding Machine-Manual Type – Bec Laser

New Delivery for Aluminum Laser Marker - Mold Laser Welding Machine-Manual Type – Bec Laser Detail:

Product Introduction

Today’s precision welding shops specializing in plastic injection mold, dies and tooling repair have a wide range of new technologies available to enhance their ability to provide the highest level of quality, craftsmanship, and service to their clients. One of the fastest growing technologies is the use of manual laser welding systems as an alternative to traditional microscope GTA welding.

One of the key elements in making manual laser welding applicable to Tool and Die or Mold manufacturing and repair was the development of the “free-moving” concept. In this approach, the laser generates a stationary infrared light pulse which is targeted through the microscope’s cross-hair. The laser pulse can be controlled in size and intensity.

Laser welding is ideal for modifications and repairs on molds, tools and dies whether due to damage, wear and tear, or a change in workpiece design. The process is quick, precise and will not damage surrounding surfaces.

Human-based design according to ergonomics makes the machine precise, nice-looking, stable performance, and long lifetime, more suitable for precision molds repair. It is a precise welding technology with concentrated high-heat energy of laser, which effectively processes the welding and repairing of some tiny damaged parts of the mold, such as: cracks, blisters, chipping, mold flashing, sealing edges, etc. of various molds. It is improved by the introduction of advanced German technology.

Features

1. Ceramic converging cavity is corrosion resistant and high temperature resistant, and has 8-10 years service life. The life of xenon lamp is more than 8 million times.

2. Using the most advanced light shielding system to eliminate the irritation to eyes by light during working.

3. Touch screen panel to adjust the parameters, which is simple and convenient.

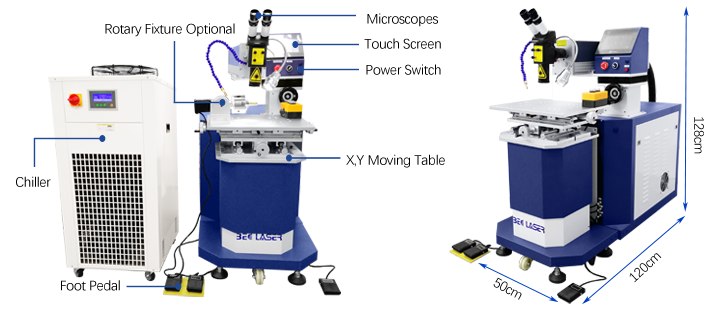

4. The work bench can be lifted, and moved in three dimensions.

5. The size of light spot can be adjusted.

6. Rotary device optional for cylindrical annular objects repair.

Application

It is suitable for precision injection molding, casting, welding mold processing and other industries; all kinds of cold alloy steel, high alloy steel forging, including Nickel welding tool steel, high-grade steel, copper alloys, beryllium copper, high-toughness aluminum and other metal material.

Parameters

| Model | BEC-MW200 | BEC-MW300 | BEC-MW400 |

| Laser Power | 200W | 300W | 400W |

| Laser Wavelength | 1064 nm | ||

| Max. Single Pulse Energy | 80J | 100J | 120J |

| Laser Type | ND:YAG | ||

| Laser Pulse Frequency | 0.1-100Hz | ||

| Pulse Width | 0.1-20ms | ||

| Welding Depth | 0.1-1.5mm | 0.1-2mm | 0.1-3mm |

| Workbench | X=450mm, Y=350mm (X,Y can be adjusted manually, Z-axis can be lifted) | ||

| Observing Systems | Microscope(optional monitoring system CCD image to enlarge) | ||

| Control System | Microcomputer program control | ||

| Power Consumption | 6KW | 10KW | 12KW |

| Cooling System | Water cooling | ||

| Power Requirement | 220V±10%/380V±10% 50Hz or 60Hz | ||

| Packing Size & Weight | Machine: 144*66*127cm, Water chiller:87*65*146cm; Gross weight around 450KG | ||

Samples

Structures

Details

Product detail pictures:

Related Product Guide:

Sticking for the principle of "Super Quality, Satisfactory service" ,We have been striving for being a superb small business partner of you for New Delivery for Aluminum Laser Marker - Mold Laser Welding Machine-Manual Type – Bec Laser , The product will supply to all over the world, such as: Macedonia, Uganda, India, Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!