Laser welding principle: Laser welding machine uses a high-intensity laser beam to radiate to the metal surface, locally heats the material in a small area, and melts the material to form a specific molten pool to achieve the purpose of welding.

Features of laser welding machine:

It is a new type of welding method, mainly for the welding of fine parts, which can complete spot welding, butt welding, stitch welding, sealing welding, etc., with high aspect ratio, small weld width, small heat affected zone, small deformation, and welding speed. Fast, flat and beautiful welding seam, no need for treatment or only simple treatment after welding, high welding seam quality, no porosity, accurate control, small gathering spot, high positioning accuracy, easy to complete automation. It uses high-energy laser pulses to partially heat the material in a small area. The energy of the laser radiation diffuses into the material through heat conduction, melts the material to form a specific molten pool, and then dissolves the two materials in contact together.

Types of laser welding machines:

Divided into two types—①Jewelry laser welding machine Mainly used for repairing holes, spot welding blisters, and repairing welding of gold and silver jewelry.

Choice of jewelry laser welding machine:

1)JEWELRY LASER WELDING MACHINE-Separate Water Chiller

Laser welding reconfigures the molecular structure of similar or dissimilar metals at the weld, making two common alloys one. The use of special microscope observation system or CCD monitoring observation system and high-speed electronic filter device can protect the operator well, the welding effect is stable and reliable, and the failure rate is low.

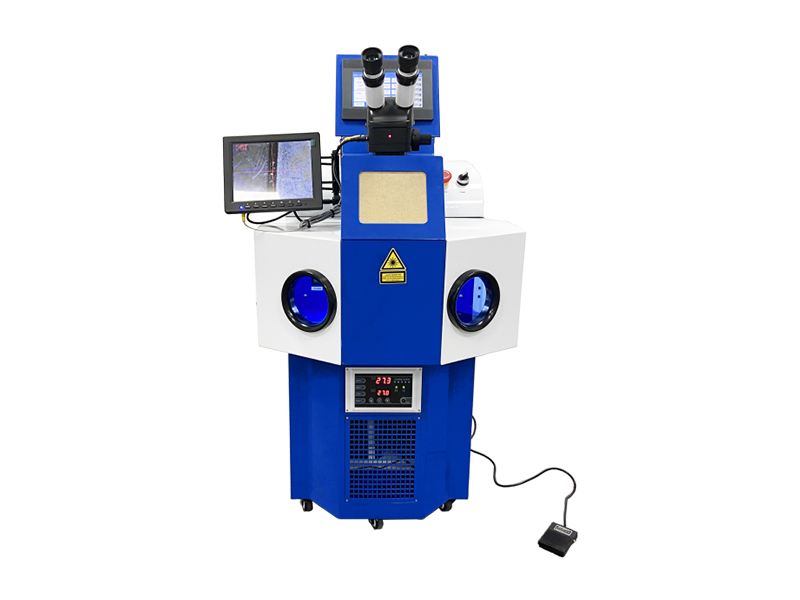

2)JEWELRY LASER WELDING MACHINE-Inbuilt Water Chiller

For filling porosity, re-tipping platinum or gold tine settings, repairing bezel settings, repairing/resizing rings and bracelets without removing stones and correcting manufacturing flaws. The observation system is a microscope observation system or a CCD monitoring and observation system.

3)JEWELRY LASER WELDING MACHINE-Desktop Model

It is a special product for jewelry laser welding, mainly used for holes and spot welding blisters in gold and silver jewelry. Laser welding machine is one of the important aspects of the application of laser material processing technology. It is characterized by the rapid positioning of the red dot, the CCD display of the observation system, and the optional microscope.

It is mainly used for laser welding repair of large and small molds. High-energy laser pulses are used to locally heat the material in a small area. The energy of the laser radiation diffuses into the interior of the material through heat conduction, and the two materials are melted and fused together.

Choice of mold laser welding machine:

1)Fiber Laser Welding Machine-Handheld Type

It adopts a new generation of fiber lasers and is equipped with high quality laser welding heads, more flexible for different processing objects. Simple operation, beautiful weld seam, fast welding speed and no consumables.

2)3-Axis Laser Welding Machine-Automatic Type

It can complete automatic spot welding, but welding stack welding and seal welding by equipped with three axes or four-dimensional ball screw table and imported servo control system, aiming at complex plane straight line.

3)Mold Laser Welding Machine-Manual Type

Mainly for the welding of thin-walled materials and precision parts. It can realize spot welding,butt welding,stitch welding,sealed welding,etc.,with high aspect ratio,small weld width,small heat-affected zone and small deformation.

4)Cantilever Laser Welding Machine-With Lazy Arm

With the cantilever arm, more suitable for big mould welding. It can be turned to all directions and angles, X, Y, Z axis movable freely, greatly solve the welding difficult, enhance the working efficiency.

The above is a brief introduction of the laser welding machine. If you want to know more, you can learn from the links on each product.

Post time: May-05-2023