Laser welding machine is a kind of welding equipment commonly used in industrial production, and it is also an indispensable machine for laser material processing. Laser welding machines have gradually matured from the early development to the present, and many types of welding machines have been derived.

Laser welding is a new type of welding method and one of the important aspects of the application of material processing technology. Laser welding is mainly aimed at the welding of thin-walled materials and precision parts. The welding process belongs to the heat conduction type, that is, the surface of the workpiece is heated by laser radiation, and the surface heat passes through The heat conduction diffuses to the inside, and the workpiece is melted to form a specific molten pool by controlling parameters such as the width, energy, peak power and repetition frequency of the laser pulse. It can realize spot welding, butt welding, stitch welding, sealing welding, etc. The welding seam width is small, the heat affected zone is small, the deformation is small, the welding speed is fast, the welding seam is smooth and beautiful, and no treatment or simple treatment is required after welding. The welding seam is of high quality, has no pores, can be precisely controlled, has a small focusing spot, and has high positioning accuracy, and is easy to automate.

Maintenance of laser welding machine:

The laser welding machine needs maintenance, and the temperature of the water tank needs to be adjusted in winter and summer. Prevent the room temperature from being too cold or too hot to affect the laser output power. It is recommended to adjust the temperature of the water tank to 3~5 degrees lower than the room temperature according to the room temperature, which can not only ensure the output power of the laser, but also ensure the stability of the laser output.

1. Water temperature setting

The cooling water temperature has a direct impact on the electro-optical conversion efficiency, stability and condensation. Under normal circumstances, the cooling water temperature is set as follows: pure water (also called low-temperature water, used to cool the laser welding machine module), the water temperature of the water circuit should generally be set at about 21 °C, and it can be appropriately set between 20 and 25 °C according to the situation. Adjustment. This adjustment needs to be done by a professional.

The water temperature of deionized DI water (also known as high temperature water, used for cooling optical parts) should be set between 27°C and 33°C. This temperature should be adjusted according to the ambient temperature and humidity. The higher the humidity, the higher the water temperature of the DI water should increase accordingly. The basic principle is: DI water temperature should be above the dew point.

2. Preventive measures such as internal electronic or optical components

The main purpose is to prevent condensation of electronic or optical components inside the laser welding machine. Ensure that the chassis is airtight: whether the cabinet doors exist and are closed tightly; whether the top hoisting bolts are tightened; whether the protective cover of the unused communication control interface at the rear of the chassis is covered, and whether the used ones are fixed. Keep the laser welding machine on and pay attention to the sequence of switching on and off. Install an air-conditioned room for the laser welding machine, activate the air-conditioning dehumidification function and keep the air-conditioning running continuously and stably (including at night), so that the temperature and humidity in the air-conditioned room are maintained at 27°C and 50% respectively.

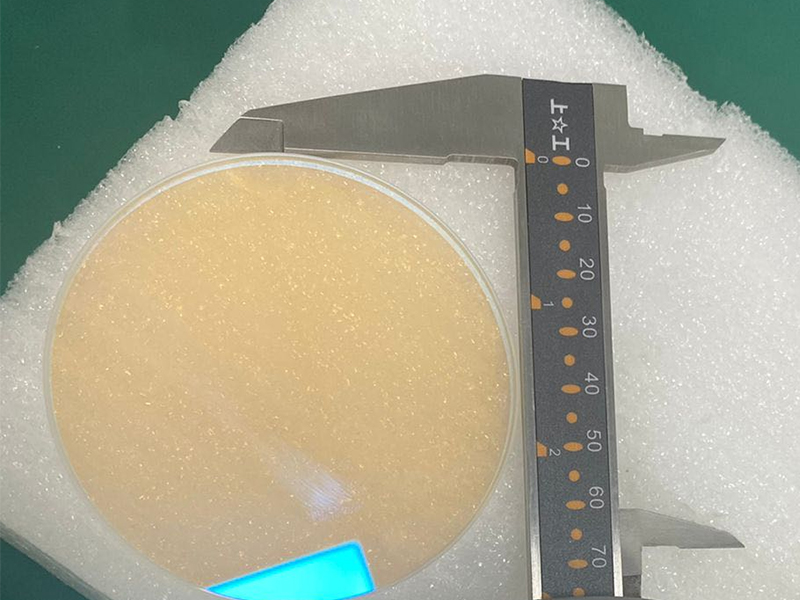

3. Check the optical path components

In order to ensure that the laser has always been in a normal working state, after continuous operation or when it is stopped for a period of time, the components in the optical path such as the YAG rod, the dielectric diaphragm and the lens protective glass should be checked before starting to make sure that the optical components are not polluted. , If there is pollution, it should be dealt with in time to ensure that each optical component will not be damaged under strong laser irradiation.

4. Check and adjust the laser resonator

laser welding machine operators can often use black image paper to check the laser output spot. Once the uneven spot or energy drop is found, the resonator of the laser should be adjusted in time to ensure the beam quality of the laser output. Debugging operators must have common sense of laser safety protection, and must wear special laser safety glasses during work. The adjustment of the laser must be carried out by specially trained personnel, otherwise other components on the optical path will be damaged due to the misalignment or polarization adjustment of the laser.

5. Laser welding machine cleaning

Before and after each work, first clean the environment to make the ground dry and clean. Then do a good job of cleaning the YAG laser welding machine equipment, including the outer surface of the chassis, the observation system, and the work surface, which should be free of debris and clean. Protective lenses should be kept clean.

Laser welding machines are widely used in the processing of dental dentures, jewelry welding, silicon steel sheet welding, sensor welding, battery cap welding and mold welding.

Post time: May-06-2023