In our lives, many people who have operated laser marking machine have certain opinions on the red light indicating system of the laser marking machine. The production of a laser marking machine contains a red light indicating system, so It is also called red light adjustment. There are many functions of red light adjustment, which plays a very important role in the positioning of laser marking machine.

When buying a laser marking machine, many buyers will ask: Does this machine have a red light adjustment function? What exactly does this “red light adjustment” do?

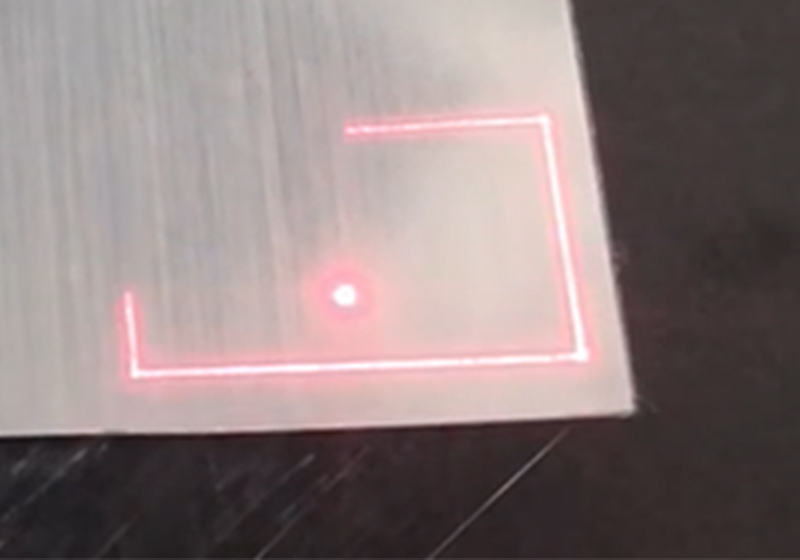

The red light adjustment is characterized by the precise positioning of the laser marking machine . Only accurate positioning can make the marking more beautiful, and it is not easy to cause various marking problems, which can improve the efficiency of marking. As the indicator light for marking and positioning of the laser marking machine, according to the different marking software, it can be divided into marking center point indication, marking pattern length and width range indication, and marking pattern overall simulation indication and other indication methods.

The red light can also be used as the focus point of the laser marking machine, that is, an indication of the marking distance. The distance where the two red light spots overlap is exactly the distance of the laser marking field lens, so that it is not necessary to measure the marking distance with a steel ruler every time the product is replaced. This reduces the operation steps and improves the marking speed.

The laser marking machine is equipped with a red light indicating system, but there is no red light, mainly for the following 5 reasons:

1. The red light is blocked, adjust it so that the red light coincides with the laser;

2. In the marking software, you have turned off the “red light preview” option, you can check this option;

3. If the red light indicator is broken, replace it with a red light pen;

4. The light path is moved, just adjust the light path;

5. The life of the red light indicator has expired. Use a multimeter to measure whether there is a 5V voltage between the two red and black bars of the red light indicator. If the voltage is 5V and there is no laser output, then the red light indicator needs to be replaced.

All in all, the infrared adjustment of the laser marking machine is very important for the user, which can not only save a lot of focusing time, but also reduce the laser marking products of different heights. In asymmetrical conditions, the work efficiency of the staff who use laser marking can be further improved.

BEC Laser provides customers with a complete set of system solutions, and can provide you with a full range of laser marking machine of all types. At the same time, we can also tailor-made exclusive models according to user needs, and can provide free proofing, technical guidance, installation training and other services.

Post time: May-15-2023