Laser marking machine is the use of laser beams to permanently mark the surface of various substances. The effect of marking is to expose the deep material through the evaporation of the surface material, or to “engrave” traces through the chemical and physical changes of the surface material caused by light energy, or to burn off part of the material through light energy, showing the required etching. pattern, text

Applications:

Can engrave a variety of non-metallic materials. Used in clothing accessories, pharmaceutical packaging, wine packaging, architectural ceramics, beverage packaging, fabric cutting, rubber products, shell nameplates, craft gifts, electronic components, leather and other industries.

1. It can engrave metal and various non-metal materials. It is more suitable for the processing of some products that require fine and high precision.

2. Used in electronic components, integrated circuits (IC), electrical appliances, mobile communications, hardware products, tool accessories, precision instruments, glasses and clocks, jewelry, auto parts, plastic buttons, building materials, PVC pipes, medical equipment and other industries .

3. Applicable materials include: common metals and alloys (all metals such as iron, copper, aluminum, magnesium, zinc, etc.), rare metals and alloys (gold, silver, titanium), metal oxides (all kinds of metal oxides are acceptable), Special surface treatment (phosphating, aluminum anodizing, electroplating surface), ABS material (electrical appliance shell, daily necessities), ink (translucent keys, printed products), epoxy resin (electronic component packaging, insulating layer).

Jewelry Laser Marking Machine:

The marking and engraving methods of the jewelry fiber laser marking machine are very flexible. You just need to enter the specified text or pattern in the software. Laser marking machines can mark and engrave the desired characters in seconds, giving jewelry the unique beauty of custom engraving. Laser marking adopts a non-contact marking process, which uses a high-energy-density laser beam to partially irradiate the surface of the material to vaporize the surface material or produce a chemical reaction of discoloration, thereby leaving lasting marks. The entire engraving process has no direct contact with the jewelry, no mechanical friction, and no damage to the jewelry. In addition, the laser spot is small, the thermal shock is also small, and the marked characters are exquisite and no damage to the jewelry.

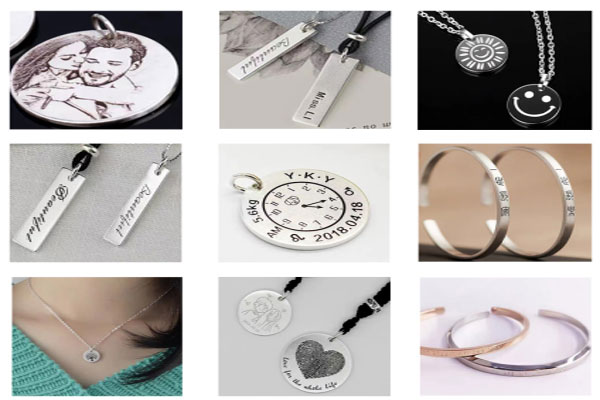

Jewelry laser marking machines are currently widely used in earrings, necklaces, rings, bracelets and other products. Competition in the jewelry industry is getting fiercer. The products in the jewelry store on the market are almost all similar. The previous processing techniques such as steel stamping, engraving and engraving technology, melting method, black and silver inlay technology, and wood grain metal are time-consuming and costly. Jewelry fiber laser marking machine has the characteristics of high precision, which is very suitable for engraving wear-resistant and durable characters on the surface of precious and small jewelry such as rings and necklaces.

Advantage:

The high-precision characteristics of laser marking machines are ideal for finishing wear-resistant permanent symbols on precious and small jewelry such as rings and collars. In today’s jewelry shopping malls, personalized markings are very popular among customers, such as words, blessings and personalized pictures with special meanings marked on jewelry. In addition, the laser marking machine can also complete various symbols on the surface of most materials such as copper, stainless steel, silver, and gold.

1. The beam quality is good, and it can precisely engrave very small workpieces, the slits are flat and beautiful, and the engraving speed is fast, bringing customers an efficient and economical processing experience;

2. High electro-optical conversion rate, no power coupling loss, no consumables, saving operating costs for customers.

3. The fiber laser has a long service life, stable laser output power, high reliability, and maintenance-free for 100,000 hours;

4. The marking speed is fast, the efficiency is high, the batch processing time of workpieces is short, and the profit per unit time and single product is maximized;

5.The special plane has strong customization ability and can be tailored according to customer needs.

The marking and engraving methods of the jewelry fiber laser marking machine

are very flexible. You just need to enter the specified text or pattern in the software. Laser marking machines can mark and engrave the desired characters in seconds, giving jewelry the unique beauty of custom engraving. Laser marking adopts a non-contact marking process, which uses a high-energy-density laser beam to partially irradiate the surface of the material to vaporize the surface material or produce a chemical reaction of discoloration, thereby leaving lasting marks. The entire engraving process has no direct contact with the jewelry, no mechanical friction, and no damage to the jewelry. In addition, the laser spot is small, the thermal shock is also small, and the marked characters are exquisite and no damage to the jewelry.

Post time: Jun-29-2023