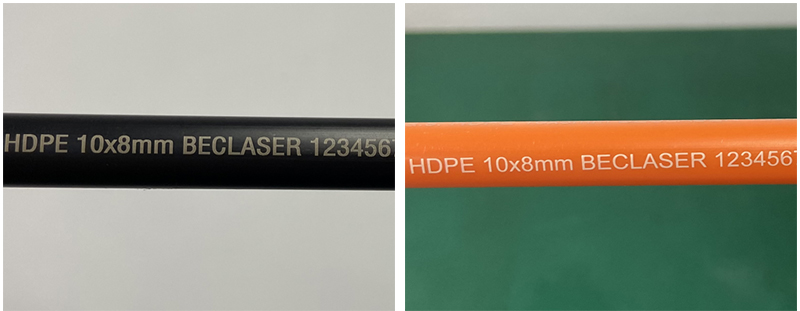

Nowadays, UV laser marking machine has entered the wire and cable industry. With its outstanding advantages, UV laser marking machine can meet the clear and durable requirements of the industry, and is very popular in the wire and cable industry.

Common product packaging in daily life has information such as the date of production, the expiration date of the product, the place of production, the ingredients contained in the food, and the storage conditions. In the past, most of these information were printed with inkjet printers, which were easily changed and erased, and could not play a good anti-counterfeiting effect. For example, cable and pipe products, the production technology threshold of such products is low, the quality of the products is mixed, counterfeiting and shoddy occur from time to time and it is difficult to control, it is often difficult for consumers to judge whether it is genuine, and its quality is directly related to thousands of companies. Electricity safety for thousands of households. In addition, many cables and pipes are exposed or buried underground for a long time, and the surface marks are easily washed away by rainwater or touched by hand, causing trouble for users in later use. However, some pipes used in the food and pharmaceutical industries have higher requirements, and the materials and printing materials are required to be non-toxic and harmless, and not easy to volatilize and fade. At this time, there is an urgent need for a non-toxic processing tool that can permanently mark information.

The application of laser technology has been widely used in various industries, and its excellent performance advantages have brought new vitality to modern industrial technology. As an advanced marking equipment, laser marking machine has become an irresistible trend in wire and cable applications. Because of its many advantages, it is replacing traditional coding equipment, especially with the current advanced laser marking machines such as UV laser marking machine . The emergence of equipment has made the application advantages of laser marking in the field of wire and cable more obvious, and has become the latest choice for wire and cable manufacturers. For wire and cable users, clear and accurate identification is a way to identify the brand. It is marked with the corresponding date, batch number, brand, serial number, QR code and other information, which can effectively resist the counterfeiting of some unscrupulous merchants. , fake and shoddy goods, effectively regulate the current wire and cable market, and also play a very important role in improving the quality of wire and cable.

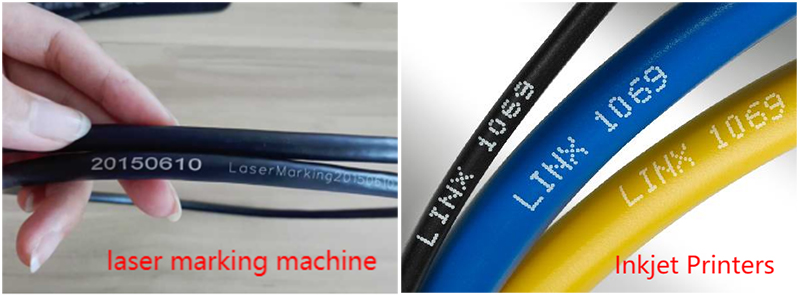

At present, the lasers used for cable coding are mainly divided into: CO2 laser marking machine, Fiber laser marking machine and UV laser marking machine . Among them, CO2 laser marking machine and Fiber laser marking machine form discoloration by burning the surface of the cable, which will Damage to the cable surface and smoke. The principle of UV laser marking machine processing is realized by photochemical ablation, that is, relying on laser energy to break the bonds between atoms or molecules, so that the material is destroyed by a non-thermal process to achieve a discoloration reaction. This cold working is of special significance in laser marking processing because it is not thermal ablation, but cold peeling that breaks chemical bonds without the side effect of “thermal damage”, so it does not affect the inner layer and adjacent areas of the machined surface. Produce heating or thermal deformation and other effects. Therefore, it can carry out ultra-fine marking and special material marking, which is the first choice for customers who have higher requirements for marking effect. At present, in the industries of non-transparent plastic products, soft film packaging, cable pipes and so on, UV has good application due to its good absorption and low thermal damage. In the future, more and more cables will be marked by UV laser marking machine.

Advantages of laser marking machine:

1.No consumables, long service life and low cost.

2.High processing efficiency, computer control, easy to realize automation.

3. The laser marking machine has the advantages of no contact, no cutting force, little thermal influence, and will not damage the surface or interior of the printed object, ensuring the original accuracy of the workpiece.

4. The marking speed is fast, the computer-controlled laser beam can move at a high speed (5-7 m/s), the marking process can be completed in a few seconds, the effect is clear, long-term and beautiful.

5. A variety of options, with two-dimensional code software function option mode, can realize the focus adjustment of static marking or flying marking on the production line.

BEC Laser provides customers with a complete set of system solutions, and can provide you with a full range of laser marking machine of all types. At the same time, we can also tailor-made exclusive models according to user needs, and can provide free proofing, technical guidance, installation training and other services , whether it is a high-end customer with high requirements for processing quality, or a small and medium-sized customer with ordinary needs, you can find a laser marking machine that suits you in BEC Laser. The UV Laser Marking Machine made by BEC Laser is your best choice.

Post time: May-16-2023