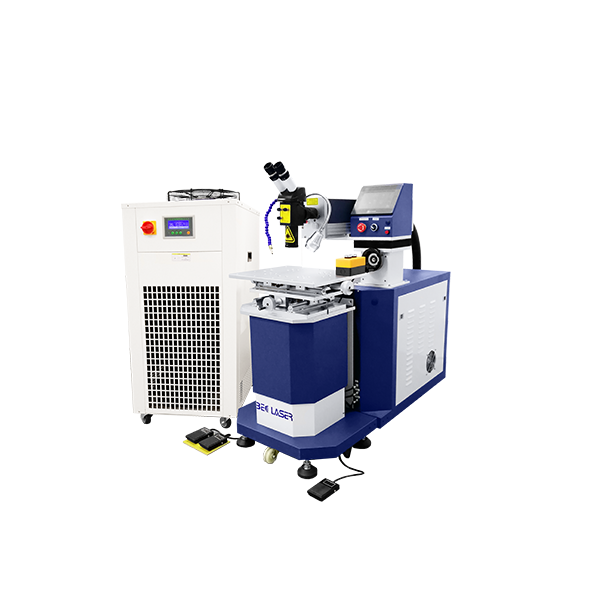

OEM/ODM China Laser Printer - Jewelry Laser Welding Machine – Desktop Model – Bec Laser

OEM/ODM China Laser Printer - Jewelry Laser Welding Machine – Desktop Model – Bec Laser Detail:

Product Introduction

Desktop Jewelry Welding Machine is an important and basic aspect of laser welding technology. It’s compact design is very convenient for using in a small space. When laser heats the surface of work-piece, the surface heat diffuses to the interior through thermal conduction and melts the work pieces by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of this unique feature, it is widely used in processing of precious jewelry or welding of precision parts. Jewelry laser spot welding machine is specially used for spot welding, repairing, re- tipping and resizing of gold/silver/titanium jewelry and small accessories. etc.

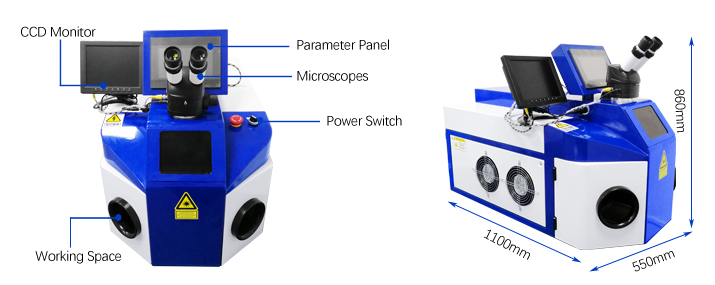

Also, It has CCD display or microscope optional.

Features

1. Red point fast positioning, CCD display, microscope optional.

2. Adjustable working table allows welding from small size to big size of work piece.

3. Fast working speed; professional jig ensures the focus fixed and makes welding easier without using CCD or microscope.

4. Able to weld with complex, profiled, or tiny letters.

5. Ultra-fine positioning rod makes the welding of tiny corner easier without changing spot position.

6. The whole machine is cooled in air-cooled mode, and the performance is stable.

7. Built-in LED lighting device, microscope built-in cross positioning mark, greatly enhance user experience and reduce work intensity.

Application

Suitable for precision casting and welding of small hardware composed of various metal materials, such as jewelry, dentures, clocks, medical treatment, instrumentation, electronic products, mechanical mold processing, automotive and other industries, especially suitable for trimming holes and gold and silver jewelry Spot welding of jewelry, welding of sand holes, repairing joints and parts of claw feet.

Parameters

| Model | BEC-JW100 |

| Laser Power | 100W |

| Laser Wavelength | 1064 nm |

| Type of Laser | ND:YAG |

| Max. Single Pulse Energy | 60J |

| Frequency Range | 0.5~20Hz |

| Pulse Width | 0.1~20ms |

| Control System | PC-CNC |

| Observation System | Microscope & CCD monitor |

| Power Consumption | 4KW |

| Cooling System | Air cooling |

| Laser Spot Size | <1.0mm |

| Pump Source | Xenon lamp |

| Electricity Demand | 3 phase 200V(380V)/50HZ ( 60HZ) |

| Packing Size & Weight | Around 117*60*81cm, gross weight around 117 KG |

Samples

Structures

Product detail pictures:

Related Product Guide:

We stay with our company spirit of "Quality, Performance, Innovation and Integrity". We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for OEM/ODM China Laser Printer - Jewelry Laser Welding Machine – Desktop Model – Bec Laser , The product will supply to all over the world, such as: Guyana, Mali, Thailand, Our Company has professional engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, Please feel free to contact us.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.