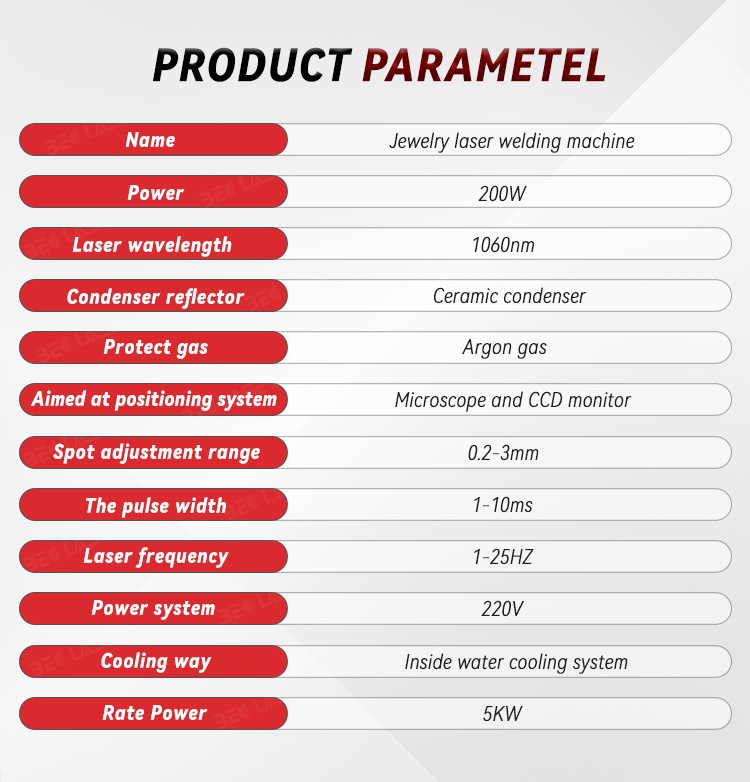

ND:YAG Jewelry Laser Welding Repair All-in-one Machine

PRODUCT INTRODUCTION

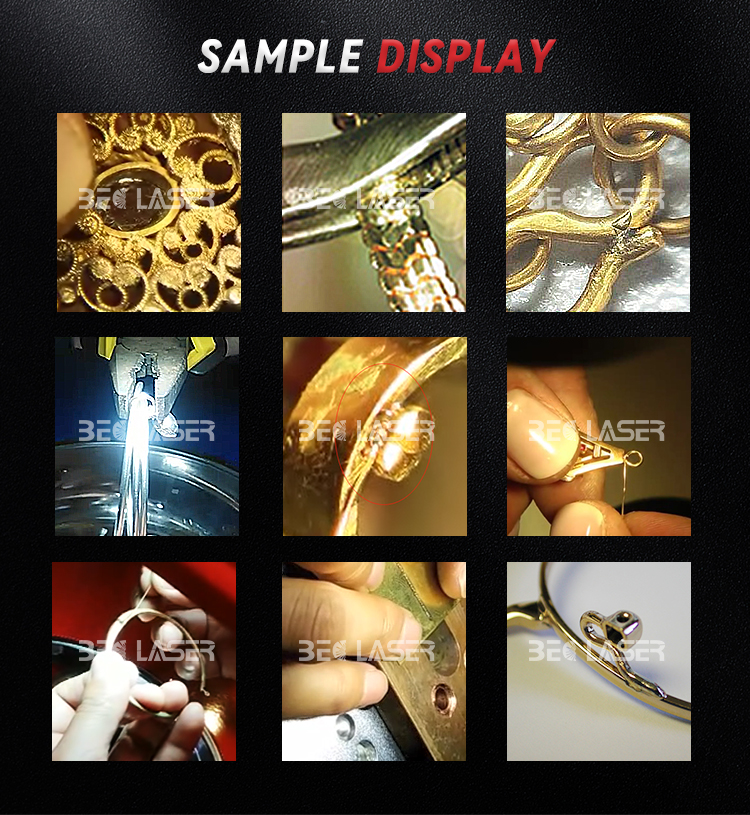

Jewelry laser welding can be used to fill porosity, re-tip platinum or gold prong settings, repair bezel settings, repair/resize rings and bracelets without removing stones and correct manufacturing defects. Laser welding recon figures themolecular structure of either similar or dissimilar metals at the point of welding, allowing the two common alloys to become one.

FEATURES

1. High quality: 24-hour continuous working capability, cavity life of 8 to 10 years, and xenon lamp life of more than 8 million times

2. The whole machine has stable performance and electric adjustable beam expand.

3. When using traditional welding technology, the metal thickness is generally required to be 0.2mm; with laser welding, it can bethinned to 0.1mm.

4.The 10X microscope system is based on the first high-defnition CCD observation system to ensure the appearance of the spot.

APPLICATION

Widely applicable to all kinds of micro parts of precision welding, such as jewelry, electronics, dental, watches,military. lt is suitable for most metal materials like platinum, gold, silver, titanium, stainless steel, cooper, aluminum